What Printing Application Works Best For My Logo

Choosing the right printing application can be a daunting task. A crucial decision that can significantly impact your brand's visibility and perception.

This article aims to guide you through the various logo printing applications available. We'll delve into digital printing:

Direct to Garment, Screen Printing, Direct to Film, Sublimation, and Embroidery techniques.

Each method has its unique benefits and limitations. Understanding these can help you make an informed decision that aligns with your branding needs, quality expectations, and budget.

This guide is for anyone who owns a small business, works in marketing, or wants to learn about logo printing." We'll provide insights into each technique, helping you choose the one that best suits your specific needs.

By the end of this article, you'll have a clear understanding of what printing application works best for your logo. Let's get started.

Understanding Logo Printing Applications

Logo printing applications are techniques used to apply a logo onto various materials. These applications play a crucial role in branding, helping businesses establish a strong visual identity.

The choice of printing application can influence the quality, durability, and cost of your printed logos. It can also affect the flexibility of design, color vibrancy, and the types of materials you can print on. Understanding these applications can help you choose the most suitable method for your logo printing needs.

Direct to Garment (DTG) Printing

Direct to Garment (DTG) printing is a popular logo printing application. It works by directly applying ink to the fabric, making it ideal for detailed and colorful designs.

DTG printing offers several benefits. Printing logos with multiple colors is simple and affordable, with no added fees for full-color printing. This makes it a cost-effective option for small runs.

However, DTG printing has its limitations. Printing large orders is less cost-effective because of the time-consuming printing process. Also, the vibrancy of colors may vary depending on the fabric used.

Here are the key points to remember about DTG printing:

- Ideal for detailed and colorful designs

- Full-color printing with no setup fees

- Cost-effective for small runs

- Less suitable for large orders

Color vibrancy may vary with fabric

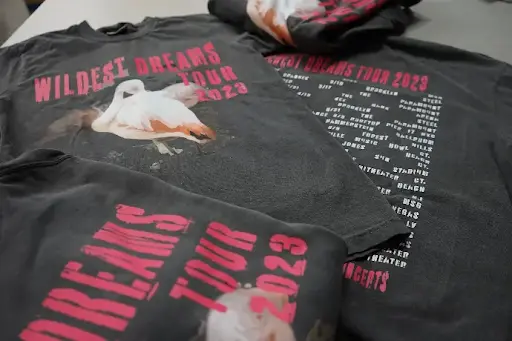

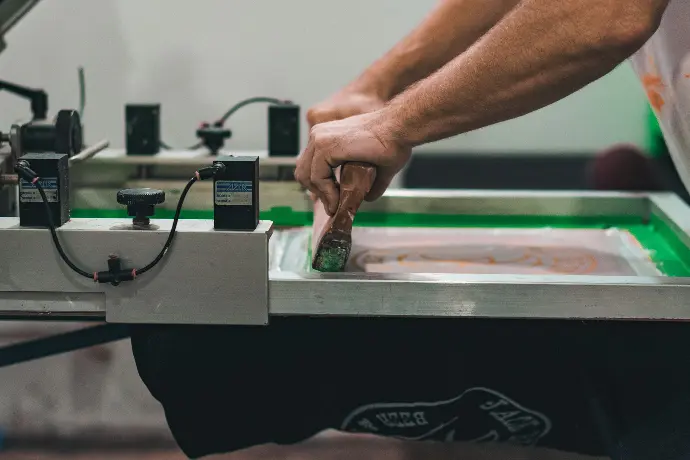

Screen Printing

Screen Printing is another widely used logo printing application. It involves pushing ink through a mesh screen onto the fabric. This method is particularly popular for large batch production

One of the main advantages of Screen Printing is its durability. The ink penetrates deeply into the fabric, resulting in vibrant and long-lasting prints. Also cost-effective for larger orders because of the economies of scale.

However, Screen Printing requires setup fees and screens for each color. This can increase the cost for designs with multiple colors. Also, the complexity of the design can affect the final print quality.

Here are the key points to remember about Screen Printing:

- Ideal for large batch production

- Offers durable and vibrant prints

- Cost-effective for larger orders

- Requires setup fees and screens for each color

- Design complexity can affect print quality

Direct to Film (DTF) Printing

Direct to Film (DTF) printing is a newer method in the logo printing industry. It involves printing the design onto a film, which is then transferred onto the fabric. This method is gaining popularity due to its flexibility.

DTF printing can be used on a wide range of fabrics, including cotton, polyester, and blends. It also offers vibrant colors, similar to DTG, but with a more flexible application process.

However, DTF printing may not be as cost-effective for large runs as other methods. It also requires specific equipment and materials, which can increase the initial investment.

Here are the key points to remember about DTF Printing:

- Suitable for a wide range of fabrics

- Offers vibrant colors

- More flexible application process

- May not be cost-effective for large runs

- Requires specific equipment and materials

Sublimation Printing

Sublimation printing is a unique process that uses heat to transfer dye onto synthetic materials. This method works well for polyester-rich fabrics and is commonly used for sportswear and promotional items.

One of the key advantages of sublimation printing is the permanence of the print. The dye becomes part of the fabric, making it resistant to fading and washing.

However, sublimation printing has its limitations. Only suitable for light-colored, polyester-rich fabrics. Dark or cotton fabrics are not suitable for this method.

Here are the key points to remember about Sublimation Printing:

- Ideal for polyester-rich fabrics

- The print is permanent and resistant to fading

- Only suitable for light-colored fabrics

- Not suitable for dark or cotton fabrics

Embroidery for Logos

Embroidery is a premium option for logo application. It involves stitching your logo directly onto the fabric, creating a textured and professional appearance.

This method is highly durable and can withstand heavy washing and usage. Often used for uniforms and high-quality merchandise.

However, the complexity and size of your design can influence the viability of embroidery. Small and intricate designs may not be suitable for this method.

Here are the key points to remember about Embroidery:

- Provides a premium, textured look

- Highly durable and suitable for heavy usage

- Design complexity and size can influence viability

- Ideal for uniforms and high-quality merchandise

Factors to Consider When Choosing a Logo Printing Application

When choosing a logo printing application, several factors come into play. When you are deciding on a purchase, there are several factors to consider. These include the material of the merchandise, the quantity needed, and the intended usage of the item. All of these factors play a role in influencing your decision.

For instance, if you're printing on polyester-rich fabrics, sublimation might be your best bet. If you're producing a large batch of t-shirts, screen printing could be more cost-effective.

Remember, the right printing application can significantly impact your brand perception. So, take the time to consider all factors before making a decision.

Branding Services and Professional Assistance

Branding services can be a valuable resource when choosing a logo printing application. They can provide expert advice, taking into account your specific needs and budget constraints.

Working with professionals can also ensure the quality of your printed logos. They have the experience and knowledge to select the right printing technique that aligns with your brand identity.

Preparing Your Logo for Printing

Before you start printing, it's crucial to prepare your logo properly. This involves ensuring the design is clear, the colors are accurate, and the resolution is high enough for printing.

Remember, the quality of your printed logo can significantly impact your brand perception. So, take the time to get it right. Worth the effort.

Conclusion: Making the Right Choice for Your Brand

Choosing the right logo printing application is a crucial step in building your brand. Not just about aesthetics, but also about how your logo performs in different contexts and resonates with your audience.

Consider all the factors we've discussed: the material you're printing on, the quantity, the usage, and your budget. Remember, the best choice is the one that aligns with your brand's identity and meets your specific needs.

In the end, a well-printed logo can significantly enhance your brand's visibility and recognition. So, make your choice wisely.

Learn More of about Branding application's,Here

What Printing Application Works Best For My Logo