DTF Printing: A Game-Changer in Apparel Industry

The apparel industry has seen remarkable advancements in printing technologies over the years. One of the most recent and revolutionary methods is Direct-to-Film (DTF) printing. This process is changing how custom clothing is made, with benefits that traditional methods like screen printing can't offer.

In this article, we'll dive deep into the world of DTF printing, exploring its pros and cons, the technology behind it, and why it's becoming a popular choice for custom printed apparel.

What is DTF Printing?

DTF printing is when designs are printed on film and then transferred to fabric with a heat press. DTF does not need fabric pre-treatment, making it a better choice.

The Technology Behind DTF Printing

DTF printing involves several key components and steps:

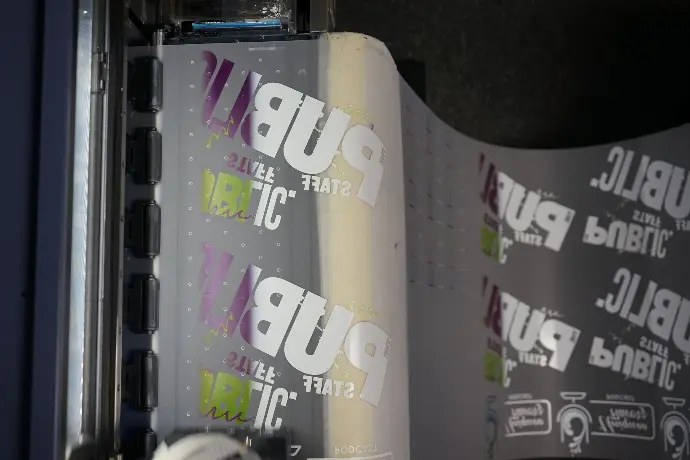

DTF Transfer Printer

A DTF transfer printer is specially designed to print intricate designs onto a film. These printers use specific types of ink that adhere well to the film and can be easily transferred to the fabric.

Heat Press Machine

Once the design is printed on the film, a heat press machine is used to transfer the design onto the fabric. The heat and pressure ensure that the ink bonds well with the fabric, resulting in a durable and vibrant print.

Special Film and Powder

The film used in DTF printing is unique and works in conjunction with a special powder adhesive. This powder is applied to the printed film and then melted during the heat press process to bond the ink to the fabric.

Pros of DTF Printing

DTF printing has several advantages over traditional methods like screen printing and heat transfer vinyl (HTV).

No Fabric Pre-treatment

Unlike Direct-to-Garment (DTG) printing, which often requires pre-treatment of the fabric, DTF printing skips this step. This saves time and reduces costs, making the process more efficient.

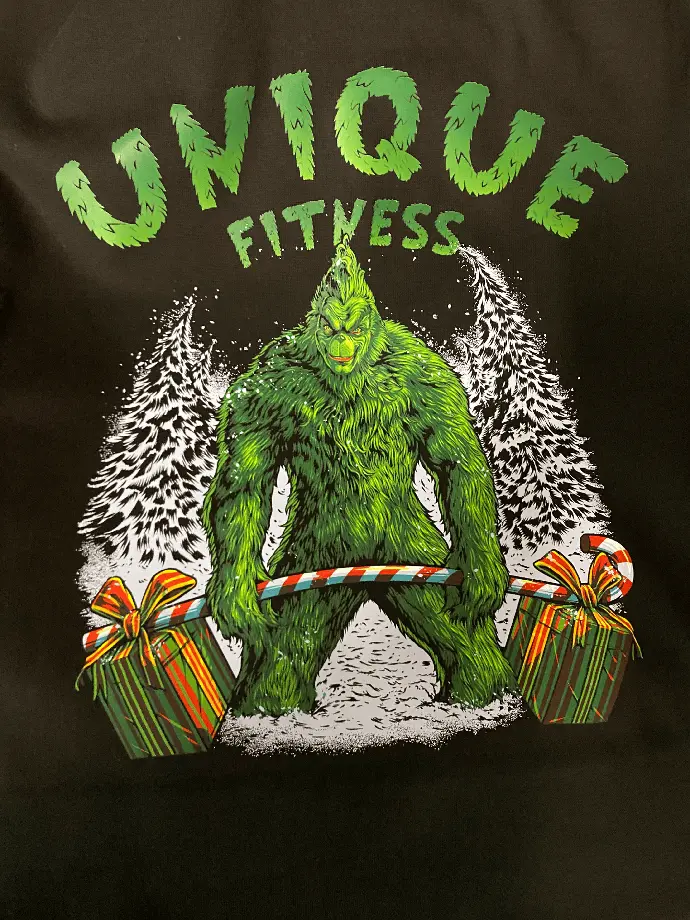

High-Quality Prints

DTF printing produces vibrant and durable prints that can withstand multiple washes without fading or cracking. The colors are often more vivid compared to other printing methods.

Cost-Effective for Small Runs

For businesses that need to produce small batches of custom apparel, DTF printing is more cost-effective than screen printing. There are no setup costs or minimum order requirements, making it perfect for one-off designs or limited edition runs.

Cons of DTF Printing

While DTF printing offers numerous benefits, it's essential to consider some drawbacks.

Initial Investment

The initial cost of purchasing a DTF printer and related equipment can be high. However, many vendors offer DTF printer financing options to make it more accessible for small businesses.

Maintenance

DTF printers require regular maintenance to ensure they operate efficiently. This includes cleaning the print heads and ensuring the powder and film are stored correctly to avoid contamination.

DTF Printer Financing Options

Given the high initial investment, many businesses may consider DTF printer financing. Financing options can make it easier to acquire the necessary equipment without significant upfront costs. Various vendors offer flexible payment plans, allowing businesses to pay for the equipment over time.

Comparing DTF Printing with Other Methods

To better understand the benefits of DTF printing, let's compare it with other popular apparel printing methods.

DTF vs. Screen Printing

Screen printing has been a staple in the apparel industry for decades. It involves creating stencils (screens) for each color and then applying ink through these screens onto the fabric. While screen printing is excellent for large runs and produces durable prints, it has several limitations:

- Setup Costs: Screen printing requires creating screens for each color, which can be costly and time-consuming.

- Limited Color Range: Complex designs with multiple colors can be challenging and expensive to produce.

- Fabric Limitations: Screen printing works best on cotton fabrics and may not adhere well to other materials.

DTF vs. Heat Transfer Vinyl (HTV)

Heat Transfer Vinyl (HTV) involves cutting designs from colored vinyl sheets and then applying them to fabric using a heat press. While HTV is popular for custom t-shirts and small runs, it also has its drawbacks:

- Limited Detail: HTV is not suitable for intricate designs or gradients.

- Layering Issues: Multi-color designs require layering different vinyl sheets, which can result in a bulky feel.

- Durability: HTV prints may peel or crack over time, especially after multiple washes.

Real-World Applications of DTF Printing

DTF printing is gaining popularity in various sectors of the apparel industry. Here are some real-world applications:

Custom Apparel

DTF printing is perfect for custom apparel businesses that offer personalized t-shirts, hoodies, and other garments. The ability to print intricate designs in vibrant colors makes it a favorite for custom orders.

Promotional Products

Companies can use DTF printing to produce promotional products like branded t-shirts, tote bags, and caps. The cost-effectiveness of DTF printing for small runs makes it ideal for promotional campaigns and events.

Fashion Industry

Fashion designers are increasingly adopting DTF printing to create unique and limited-edition pieces. The versatility and high-quality prints make it suitable for various fabric types and design styles.

Conclusion

DTF printing is indeed a game-changer in the apparel industry. Its versatility, high-quality prints, and cost-effectiveness for small runs make it an attractive option for custom apparel businesses. While there are some challenges, such as the initial investment and learning curve, the benefits far outweigh the drawbacks.

As technology advances, DTF printing will become more efficient and accessible, changing how custom clothing is made. Whether you're an experienced business or just starting out, investing in DTF printing could help your business grow and succeed.

DTF Printing: A Game-Changer in Apparel Industry