What s the Difference Between Screen Printing and Direct-to-Film

In the world of custom apparel printing, understanding the different methods available is crucial for achieving the desired result. Two of the most discussed techniques are screen printing and direct-to-film (DTF) printing. While both methods are popular, they cater to different needs and preferences. This guide will explore these two printing methods, highlighting their distinct features and helping you decide which is best suited for your project requirements.

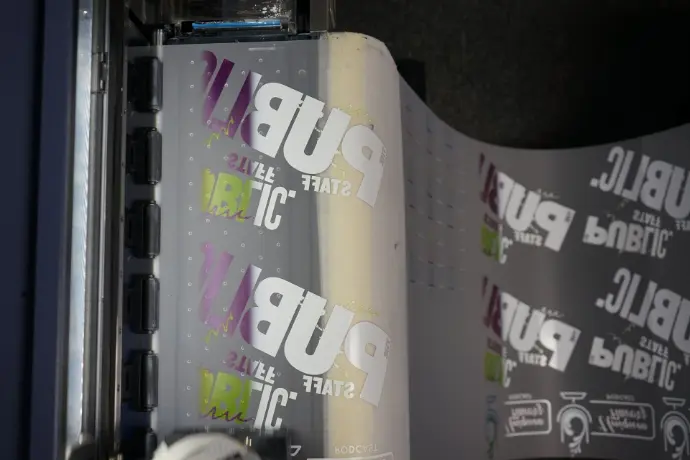

Understanding Screen Printing

Screen printing, also known as silkscreen printing, has been a staple in the textile printing industry for decades. It is a technique that involves creating a stencil, or "screen," which is used to apply layers of ink onto the fabric.

Pros of Screen Printing

- Quality Prints: Screen printing is renowned for its ability to produce vivid, durable prints that can withstand the test of time.

- Durability: The inks used in screen printing penetrate deeply into the fabric, ensuring that the prints are resistant to fading and wear, even after multiple washes. This makes it ideal for sportswear and other apparel subjected to frequent use.

- Cost-effective for Bulk Orders: The setup process, while initially time-intensive, becomes highly efficient for large orders. Once the screens are prepared, the cost per unit significantly decreases, making it an economical choice for large-scale productions.

Cons of Screen Printing

- Set-up Time: Preparing the screens for printing can be a labor-intensive process, particularly for designs with multiple colors. Each color requires a separate screen, which can increase the setup time and cost.

- Limited Detail: Fine details and complex patterns can be challenging to reproduce accurately with screen printing. It's best suited for simpler designs with fewer color variations.

- Environmental Impact: Traditional screen printing processes can be resource-intensive, utilizing significant amounts of water and chemicals. However, many companies are adopting more sustainable practices to mitigate this impact.

Exploring Direct-to-Film (DTF) Printing

Direct-to-film printing is a cutting-edge technology that has been gaining traction in the custom apparel industry. Unlike traditional methods, DTF printing involves printing designs onto a special film, which is then transferred onto fabric using a heat press.

DTF printing is particularly advantageous for small orders and one-off projects due to its minimal setup requirements. The technology allows for quick changes in design, making it ideal for businesses that need to offer personalized products or cater to fast-changing trends. Additionally, the process is less labor-intensive, which can translate to quicker turnaround times.

Pros of DTF Printing

- Versatility: One of the standout features of DTF printing is its ability to print on a wide range of materials, including both natural and synthetic fibers. This flexibility makes it suitable for various applications, from fashion to promotional items.

- Detail and Color Range: DTF excels in producing high-resolution images with vibrant colors and fine details. It can easily handle gradients and complex designs, which are often a challenge for traditional screen printing.

- Quick Setup: Without the need to prepare physical screens, DTF printing significantly reduces the setup time. This makes it an attractive option for smaller orders or when rapid production is required.

Cons of DTF Printing

- Durability Concerns: While DTF prints are generally durable, they may not offer the same level of longevity as screen-printed items, particularly under frequent washing and heavy wear. This is an important consideration for apparel that needs to endure rigorous use.

- Cost for Large Orders: The cost-effectiveness of DTF diminishes with larger orders. Unlike screen printing, where costs decrease with volume, DTF remains relatively constant per unit, making it less economical for bulk production.

- Film Waste: The use of special transfer films in the DTF process can lead to waste, raising concerns about its environmental impact compared to more sustainable alternatives.

Screen Printing vs. Direct-to-Film: Side-by-Side Comparison

To decide between screen printing and DTF, it's crucial to understand how they compare in various aspects. Here’s a closer look at the key differences that might influence your decision.

Setup and Production Speed

- Screen Printing: The setup phase in screen printing requires time and effort due to screen preparation. However, once the screens are ready, the process can handle large runs efficiently, making it fast for mass production.

- DTF Printing: The digital nature of DTF allows for a much faster setup since it bypasses the need for physical screens. This makes DTF ideal for short runs and situations that demand quick turnarounds, such as custom or limited edition items.

Design Complexity and Detail

- Screen Printing: Best suited for designs that feature solid colors and less intricate details. It can struggle with reproducing gradients or highly detailed imagery, which may require simplification for optimal results.

- DTF Printing: Thanks to digital technology, DTF can easily handle complex and detailed designs, including those with intricate patterns and smooth color transitions. This capability makes it a preferred choice for designs that demand precision and a wide color range.

Cost Efficiency

- Screen Printing: Economically advantageous for bulk orders due to the reduced per-unit costs once screens are prepared. The larger the order, the more the cost benefits are realized, making it a staple for large-scale printing needs.

- DTF Printing: While potentially more expensive for large orders, DTF is economical for small to medium-sized orders thanks to its minimal setup costs. This makes it a versatile option for businesses that deal with frequent design changes or custom work.

Durability and Longevity

- Screen Printing: Known for its superior durability, screen printing produces prints that withstand multiple washes and retain their vibrancy over time, making it ideal for long-lasting apparel.

- DTF Printing: Offers good durability, although it might show signs of wear quicker than screen-printed items. It's a solid option for items that do not require the extended longevity of screen prints.

Choosing the Right Printing Technique

Selecting the right printing method involves balancing several factors to meet your project's specific needs. Here are some considerations to guide your decision:

- Order Size: Screen printing is generally more cost-effective for large orders due to economies of scale. If you're planning a smaller run, DTF might be more suitable due to its lower initial setup costs.

- Design Complexity: The level of detail in your design can dictate the choice of printing technique. DTF is preferable for intricate and colorful designs, while screen printing works well for simpler, bold graphics.

- Material Type: While both methods can work on various materials, DTF offers greater flexibility, particularly for synthetic fabrics. This versatility can be crucial when working with diverse textile types.

- Budget: Carefully analyze the total cost, including setup and per-item expenses, to ensure the chosen method aligns with your budget constraints. Consider the long-term value and quality of prints, especially if durability is a priority.

Conclusion

Screen printing and direct-to-film printing each hold unique advantages in the realm of custom apparel printing. Understanding the strengths and limitations of each can greatly influence the outcome of your project. Whether your focus is on durability, design detail, or cost, selecting the right method will help achieve your desired results.

By being informed about these printing techniques, you are better equipped to create custom apparel that not only meets aesthetic expectations but also stands up to practical demands. Next time you're ready to produce custom designs, you'll have the knowledge to choose the best method for your needs.

Happy printing!

What s the Difference Between Screen Printing and Direct-to-Film?